Tomorrowland: how innovation and sustainability will change the fashion panorama.

On Wednesday, 24th April 2019, Fashion Revolution hosted our fifth annual Fashion Question Time, a powerful platform to debate the future of the fashion industry during Fashion Revolution Week. This year Fashion Question Time was hosted for the first time at the V&A museum and opening the event up to the public for the first time. The theme this year was Tomorrowland: how innovation and sustainability will change the fashion panorama.

Chaired by Baroness Lola Young of Hornsey, this year’s panel brought together leading figures across government and the fashion industry to discuss the future of the fashion industry.

Attendees included high-level fashion industry representatives from across the sector, global brands, retailers, press, MPs, influencers, and NGOs. Panelists included Mary Creagh, MP and Chair of the Environmental Audit Committee; Laura Balmond, Project Manager, Ellen MacArthur Foundation; Mark Sumner, Lecturer in Sustainability, Fashion & Retail, University of Leeds, and Hendrik Alpen, Sustainability Engagement Manager, H&M Group.

After a welcoming speech from Tim Peeve, an opening speech was made by Sarah Ditty, Policy Director for Fashion Revolution:

“There is an ocean of truth lying undiscovered before us when it comes to the fashion industry of tomorrow. We urgently need to focus on innovation and we need sustainability to be scaled up.”

Below we have selected some questions and answers that were discussed over the 1 hour ½ debate during Fashion Question Time 2019 at the V&A:

Olivia Shaw, Campaign Support Officer for #LoveNotLand

fill and London Waste & Recycling Board asked:

“In a world with finite resources, why does the fashion industry waste around three quarters of what it creates and how are we going change this model to create a fair system for all?”

Laura Balmond, Project Manager, Ellen MacArthur Foundation: It’s not possible to continue as we go on… The amount of clothes produced is rapidly increasing – and we are using clothes 40% less. Less than 1% of materials are going back into fashion we make… We need a huge systemic rethink .. I believe that the circular economy will be business-led. We need businesses to get behind this common vision… The current system doesn’t work. The leaders will continue to push ahead – will the others exist in 5 years time?

Mark Sumner, Lecturer in Sustainability, Fashion & Retail, University of Leeds: Technically there are lots of solutions but there’s no motivation… We have the opportunity to change this and legislation plays an important role. The fashion industry has been around for thousands of years. It plays an important role in self-esteem and identity, plays an important part in our lives. But we can’t stick with the model we have at the moment, we need to change. The Modern Slavery Bill is a good starting point but we need more legislation. More innovative structures in place to penalise businesses – the responsibility needs to be across the whole system.

Mary Creagh, MP and Chair of the Environmental Audit Committee: The current fashion industry model promotes over consumption and under utilisation. My concern is that the policy space in this country, which has historically been a leader on these issues, has been crowded out by the Brexit psychodrama and the space for creative and necessary responses to this is being handed to us. We’re in a unique situation where the public is dragging the Government. We debated the environment twice in Parliament twice yesterday so things are changing but we all need to think about our overconsumption… We also need to strengthen regulation to require greater executive level accountability for tackling modern slavery and reducing greenhouse gas emissions in business and supply chains.

Hendrik Alpen, Sustainability Engagement Manager, H&M Group: Moving to a circular model makes business sense. Right now, H&M operates one of the biggest global take-back schemes.

Sarah Ditty, Fashion Revolution, Policy Director on behalf of Labour behind the Label asked:

The one safety initiative that came out of the Rana Plaza collapse, the Accord on Fire and Building Safety in Bangladesh, is at risk of being expelled from the country at the moment, putting all the progress made in the last six years at risk. At the moment over 50% of the factories still lack adequate fire alarm and detection systems and 40% are still completing structural renovations, these life-saving remediations need to be overseen by the Accord. With the Accord under threat, how can innovations in transparency create a better future for garment workers?

Laura Balmond, Project Manager, Ellen MacArthur Foundation: With innovations around transparency, relies purely on the information that is inputted at the very beginning. So, this then raises the question of how do we verify that and how do we ensure the information you are receiving is correct? Therefore, what are the financial incentives to improve the system? We must incentivise accurate data inputting.

Hendrik Alpen, Sustainability Engagement Manager, H&M Group: The Accord is a very well working mechanism. So, we as a brand, and other brands hope it will continue. Last year 98% of our suppliers were compliant with the Accord’s requirements, and this year, it will be 100% compliance. You talk about incentives, so that’s a sort of incentive we can create to get something back for the work we are investing, besides, you know, it’s the right thing to do. This can also create a level playing field between brands and this is very crucial to make informed choices.

Mary Creagh, MP and Chair of the Environmental Audit Committee:

The real costs of what goes into those clothes are not truly priced. We will only have change if we price clothing based on the material, the labour, and carbon emissions. Those costs are currently passed onto the countries of production… Currently, it’s down to little NGOs to police big brands. Footlocker doesn’t provide an anti-slavery statement on their website, for example… We must make accountants and CEOs accountable for slavery and emissions. Anyone with a pension fund can buy shares in a business, and as a shareholder, you can go to AGMs and to put pressure on these brands.

Sara Arnold of Extinction Rebellion asked:

To have a chance of avoiding the worst effects of the climate and ecological collapse, we must get to net zero carbon by 2025 and halt the loss of biodiversity. The mobilisation we need is unprecedented and as an industry, we should be declaring climate and ecological emergency and acting as so. If this was treated as the emergency that it is, would there be any place for fast fashion? Would there be a place for fashion at all?

Hendrik Alpen, Sustainability Engagement Manager, H&M Group: Obviously, it is hard to say we shouldn’t exist! But I can relate to the thoughts. So, our job is to reduce the impact of what we do. So that’s why we set the goal to be climate positive by 2040, that may be too late, but we are discussing timelines. We have made changes across our stores, and office to be powered by renewable electricity. So, the challenge we have is how do we bring that into the supply chain? And our first goal is to have a climate neutral supply chain by 2030. That’s a huge challenge, we don’t know how to do that, but that’s the challenge we are taking on and we have to take on. Then the question is how can we continue to operate with such a business model which still brings fashion to the people but how do we do that in a better way? Our business model is based on selling products and it still will be for a while and on the other hand, that means jobs for people, joy for people but we need to find a different way.

Laura Balmond, Project Manager, Ellen MacArthur Foundation:

Think of the global population, what do people want, what do people need. Firstly, we need clothes, but then we have a prospect of fashion. Fashion is creative and meets a variety of needs of the people. So you’ve got on the one hand, Instagram bloggers who wear many different outfits and that’s how they’ve learnt to operate. And that’s okay, we don’t want to stifle creativity or fun. At the opposite end of the spectrum, you’ve got the guy that’s had his pair of Levi’s and loves them and doesn’t want them to ever wear out and he’s set for life. So how can the fashion industry rise to the challenge of meeting both these needs and still continue to exist? This can lead to interesting things coming out of this, for instance, an organisation that curates a digital wardrobe, so why do they necessarily need to own clothes at all…This is the end where rental models, swapping will be the way to keep clothes in use for as long as possible, just not with the same person. Then, on the other hand, we need to create well made, durable and repairable clothing. And that’s the challenge for the fashion industry: how can it rise to better meet the needs of the consumers?

Mark Sumner, Lecturer in Sustainability, Fashion & Retail, University of Leeds:

We’ve got 11 years to solve climate change, and I suspect it’s going to be less than that. So I agree, that it’s not fast enough. But I think you need to understand that its systemic part of culture and the part that the fashion industry plays in it. Fashion plays a really important role in our lives, for self-esteem, identity, it’s about projecting our position in society. It a really important part of our lives… I think it’s really interesting when people talk about fast and slow fashion, I go around fabric mills and garment factories, you can see excellent best practice happening in fast fashion supply chain and at the same time, around the corner you see absolutely diabolical conditions in factories supplying to luxury brands, sometimes run by the mafia. So, to think that luxury, fast fashion and slow fashion are different concepts is false. I think what we need to be looking at is brands and retailers that are doing good things, H&M, for example, are trying lots of different models, they haven’t got the answers yet but at least they are trying. Some brands out there don’t even know they have to ask the question about climate change, it’s not on their agenda at all. Those organisations are the ones we really need to metaphorically give them a kick. Different business models need to be developed but that does require significant change, so it’s also about changing the way we behave.

Mary Creagh, MP and Chair of the Environmental Audit Committee:

Thank you [to Extinction Rebellion] for creating the operating space for MP’s like me, who have always been a bit of a lonely voice, to become normalised.

But also, while there is a climate emergency, there’s also a social emergency on hand. And we need to tackle both of these things together. And switching to a low-carbon economy, we have to make it adjust transitionally, we have to make sure we don’t create winners and losers, so that fashion shouldn’t just become something for rich people to enjoy. So, when we look at how we are going to transition, we have got problems with our transport, in agriculture and the way we fuel our homes. So those are the three policy challenges for government. Had we moved from our over-consuming society very quickly, we aren’t going to get to net zero by 2025. The science will tell us what to do to get to net zero by 2050, and then in five years’ time to 2040 and then we’ll aim to get there for 2035. We have wasted the last 10 years, we’ve had no new policy in this country to change behaviour and we’ve done some policy mistakes along the way. I think fashion needs to set out it’s roadmap to net zero. It needs to say how we get to net zero and the target needs to be legally enforceable and not just voluntary.

Dr Mark Sumner, Lecturer in Sustainability, Fashion & Retail, University of Leeds:

This isn’t just about fashion, it’s a culture of consumption. There are brands doing good stuff who are being lambasted by the press and the ones that aren’t doing anything are slipping into the shadows.

Closing Fashion Question Time 2019, Orsola de Castro, co-founder of Fashion Revolution, made a powerful closing speech:

“There is absolutely no excuse anymore. We all have to do what is required of us as people, people working in companies, in governments, in education, in the media, and at home. We have to fight the system and we have to fight our lifestyle. We can’t do this without information and we can’t access verifiable, comparable and understandable information without transparency and public disclosure… We have to move from a culture of exploitation to one of appreciation and place respect for resources and for each other before every deed and every process.”

The other questions asked were:

Antonio Roade, Senior CSR Manager, New Look asked:

Technology will be vital to transition towards a circular economy; and we keep on seeing big companies investing millions collaborating with different research institutions; in different areas and often with no clear outputs. How do we coordinate different initiatives and who should be taking the lead on this (research institutions, governments or brands)?

Elle L, Artist, Expert Advisor in Fashion and Media to United Nations Environment Programme asked:

As we know, fast fashion uses a lot of synthetics which we in the room and the government now know to be highly toxic and damaging to the environment — do you think that a tax can and should be implemented to minimise or how do we phase out the amount of synthetics produced?

Julie Hill, Chair of WRAP asked:

What are the best tools to drive resource efficiency and transparency in the fashion supply chain?

Jennifer Eweh, Designer and Entrepreneur, Eden Diodati asked:

What are the opportunities and challenges involved with automation, blockchain, and artificial intelligence being used within the fashion supply chain?

Siobhan Wilson, Owner, The Fair Shop asked:

Small business and organisations have been driving change in communities across the country and beyond in making, repairing, reinventing and reusing. How can these businesses be nurtured and supported more here in the UK, so they can flourish at a greater scale and gain further exposure to a mainstream fashion audience?

Jasmine Hemsley, Cook, Author and wellness expert, asked:

What will our future look like without sustainable fashion being commonplace?

A very special thank you to the Edwina Ehrman for opening the V&A to Fashion Revolution’s Fashion Question Time and to the rest of the V&A team for your efforts in making this event a success. And a thank you to Sienna Somers and the rest of the Fashion Revolution team for organising this event.

All images Copyright Rachel Manns / www.rachelmanns.com / @rachel_manns / Rachel Manns is an internationally commissioned freelance photographer based in London, UK. She has spent the last decade shooting for a range of clients all over the world. She has a strong passion for sustainability and human rights. With fierce ethical values and a beautiful visual style, Rachel’s work perfectly intertwines the two. Her aim is to use her camera to aid positive change globally, whether that’s politically or commercially, whilst never compromising on aesthetic. Get in contact for rates.

WHY SHOULD BRANDS PUBLISH SUPPLIER LISTS?

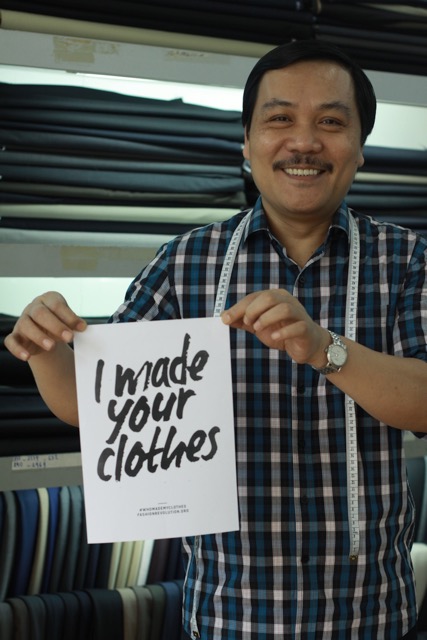

Publicly disclosed supplier lists are helping trade unions and workers rights organisations to address and fix problems which workers are facing in the factories that supply major brands and retailers. This sort of transparency makes it easier for the relevant parties to understand what went wrong, who is responsible and how to fix it. It also helps consumers better understand #whomademyclothes.

“Knowing the names of major buyers from factories gives workers and their unions a stronger leverage, crucial for a timely solution when resolving conflicts, whether it be refusal to recognise the union, or unlawful sackings for demanding their rights. It also provides the possibility to create a link from the worker back to the customer and possibly media to bring attention to their issues.” says Jenny Holdcroft, the Assistant General Secretary of IndustriALL Global Union

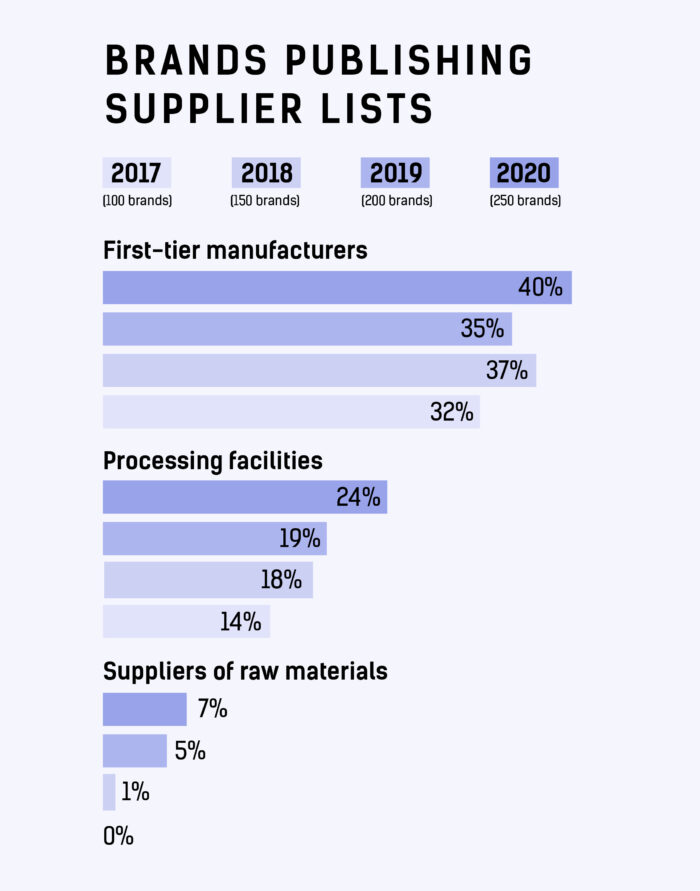

HAVE WE SEEN AN INCREASE IN BRANDS PUBLISHING SUPPLIER LISTS?

Since we began the Fashion Transparency Index in 2016, we have seen a significant increase in the number of brands publishing their first tier, processing and raw materials suppliers. In our 2020 edition of the Fashion Transparency Index, 101 out of 250 brands (40%) are publishing their first-tier manufacturers, up from 35% in 2019. These are the facilities that do the cutting, sewing and finishing of garments in the final stages of production.

60 out of 250 brands (24%) are publishing some of their processing facilities, up from 19% in 2019. These are the sorts of facilities that do ginning and spinning of yarn, knitting and weaving of fabrics, dyeing and wet processing, leather tanneries, embroidering and embellishing, fabric finishing, dyeing and printing and laundering.

And, 18 out of 250 brands (7%) are publishing some of their raw material suppliers, up from 5% in 2019. These suppliers are those that provide brands and their manufacturers further down the chain with raw materials such as cotton, wool, viscose, hides, rubber and metals.

HOW MANY BRANDS ARE NOW PUBLISHING SUPPLIER LISTS?

We have looked at large brands (over £36 million annual turnover) beyond the Fashion Transparency Index to count the number that are publishing lists of their suppliers. Below, you will find a list of over 200 brands that are publishing their first-tier manufacturers, 60 brands that are publishing their processing facilities and 21 brands that are publishing their raw material suppliers.

We are always pushing brands to provide more information about the people who make their clothes, and you can encourage them to do so too. Always ask the brands you buy #WhoMadeMyClothes. You can do this by tagging your favourite brands on social media and using this hashtag, or you can use our automated email tool to get in touch with them directly.

Brands who publish first-tier supplier lists

First-tier/ Tier One/ manufacturing suppliers are those which have a direct relationship with buyer e.g. production units, Cut Make Trim (CMT) facilities, garment sewing, garment finishing, full package production and packaging and storage.

& Other Stories (H&M group)

Abercrombie & Fitch

Adidas

ALDI-Nord

ALDI SOUTH

Amazon

Ann Taylor

Anthropologie (URBN)

ARROW (PVH)

ASICS

Aldi North

ASOS

Athleta (GAP Inc.)

Autograph (Speciality Fashion Group)

Banana Republic (GAP Inc.)

Berghaus (Pentland Brands)

Berlei (Hanes)

BESTSELLER

BigW (Woolsworth Group)

Black Pepper (PAS Group)

Boden

Bon Prix

Bonds (Hanes)

Boxfresh (Pentland Brands)

Brand Collective

Brooks Sports

Burton (Arcadia)

C&A

Calvin Klein (PVH)

Champion (Hanes)

Cheap Monday (H&M group)

City Chic (Speciality Fashion Group)

Clarks

Cole’s (Wesfarmers Group)

Columbia Sportswear Co.

Converse (NIKE, Inc)

Cos (H&M group)

Cotton:On

Crossroads (Speciality Fashion Group)

Curvation (Fruit of the Loom, Inc.)

David Jones

Debenhams

Designworks (PAS Group)

Disney

Dorothy Perkins (Arcadia)

Dressmann (Varner)

Eagle Creek (VF Corporation)

Eastpak (VF Corporation)

Eileen Fisher

El Corte Inglés

Ellesse (Pentland Brands)

Esprit

Evans (Arcadia)

Factorie (Cotton On Group)

Fanatics

Fjällräven

Forever New

Free People (URBN)

Fruit of the Loom

G-Star

Galeria Inno (HBC)

Galeria Kaufhof (HBC)

Gap

George at Asda (Walmart)

Gildan

H&M

Hanes

Helly Hansen

HEMA

Hermès

Holeproof Explorer (Hanes)

Hollister Co. (Abercrombie and Fitch Co.)

Hudson’s Bay Company (HBC)

HUGO BOSS

Hurley (NIKE, Inc)

Intermix (GAP Inc.)

IZOD (PVH)

JACK&JONES (BESTSELLER)

Jack Wolfskin

Jacqueline de Yong (BESTSELLER)

JAG (APG & Co)

Jansport (VF Corporation)

Jeanswest

JETS Swimwear (PAS Group)

Jockey (Hanes)

John Lewis

Joe Fresh (Loblaw Companies Limited)

Jordan (NIKE, Inc)

Junarose (BESTSELLER)

KangaROOS (Pentland Brands)

Kathmandu

Katies (Speciality Fashion Group)

Kaufland

Kayser (Hanes)

Kipling (VF Corporation)

Kmart Australia (Wesfarmers Group)

Lacoste

Lee (VF Corporation)

Levi Strauss & Co.

Lidl

Lindex

Littlewoods (Shop Direct)

Loblaw

Loft (Ascena)

Lord & Taylor (HBC)

lucy (VF Corporation)

Lululemon

Majestic (VF Corporation)

Mamalicious (BESTSELLER)

Mammut

Marco Polo (PAS Group)

Marimekko

Marks & Spencer

Matalan

MEC

Millers (Speciality Fashion Group)

Missguided

Miss Selfridge (Arcadia)

Mizuno

Monki (H&M group)

Monsoon

Morrisons (Nutmeg)

Name It (BESTSELLER)

Napapijiri (VF Corporation)

Nautica (VF Corporation)

New Balance

New Look

Next

Nike

Noisy May (BESTSELLER)

Nudie Jeans

Old Navy (GAP Inc.)

Only (BESTSELLER)

Only & Sons (BESTSELLER)

Outerknown (Kering Group)

Outfit (Arcadia)

OVS

Patagonia

Pieces (BESTSELLER)

Pimkie

Playtex (Hanes)

Primark

Prisma (S Group)

Puma

R.M Williams

Razzamatazz (Hanes)

Red or Dead (Pentland Brands)

Reebok (Adidas Group)

Reef (VF Corporation)

REI Co-op

Review (PAS Group)

Rider’s by Lee (VF Corporation)

Rio (Hanes)

River Island

Rivers (Speciality Fashion Group)

Rock & Republic (VF Corporation)

rubi (Cotton On Group)

Russell Athletic (Fruit of the Loom, Inc.)

Sainsbury’s – Tu Clothing

Saba (APG & Co.)

Sak’s Fifth Avenue (HBC)

Selected (BESTSELLER)

Sheer Relief (Hanes)

Sisley (Benetton Group)

Smartwool (VF Corporation)

SPALDING (Fruit of the Loom, Inc.)

Speedo (Pentland Brands)

Sportscraft (APG & Co.)

Supré (Cotton On Group)

Target

Target Australia (Wesfarmers Group)

Tchibo

Ted Baker

Tesco

The North Face (VF Corporation)

The Warehouse

Timberland (VF Corporation)

Tod’s

Tommy Hilfiger (PVH)

Tom Tailor

Topman (Arcadia)

Topshop (Arcadia)

Under Armour

Uniqlo (Fast Retailing)

United Colours of Benetton (Benetton Group)

Urban Outfitters (URBN)

Van Heusen (PVH)

Vanity Fair Lingerie (Fruit of the Loom, Inc.)

Vans (VF Corporation)

Vassarette (Hanes)

Vero Moda (BESTSELLER)

Very (Shop Direct)

Victoria’s Secret (L Brands)

Vila Clothes (BESTSELLER)

Voodoo (Hanes)

Wallis (Arcadia)

Warner’s (PVH)

Weekday (H&M group)

White Runway (PAS Group)

Wrangler (VF Corporation)

Yarra Trail (PAS Group)

Y.A.S. (BESTSELLER)

Zalando

Zeeman

Total: 204

Brands who publish processing facilities list

Processing facilities (often referred to as facilities beyond tier 1) are involved in the production of clothing whose activities could involve ginning and spinning, knitting, weaving, dyeing and wet processing, tanneries, embroidering, printing, fabric finishing, dye-houses and laundries.

Adidas

Anthropologie (URBN)

ASICS

ASOS

Banana Republic (GAP Inc.)

Bon Prix

Burton (Arcadia)

C&A

Calvin Klein (PVH)

Champion (Hanes)

Clarks

Converse (NIKE, Inc)

Debenhams

Disney

Dressmann (Varner)

Eileen Fisher

Ermenegildo Zegna

Esprit

Free People (URBN)

Gap

Gildan

G-Star RAW

H&M

Hanes

Helly Hansen

HEMA

Hermès

Jack Wolfskin

Jordan (NIKE, Inc)

Kaufland

Levi Strauss & Co.

Lindex

Lululemon

Monsoon

New Balance

New Look

Nike (Nike, Inc.)

Nudie Jeans

Old Navy (GAP Inc.)

Patagonia

Puma

Reebok (Adidas Group)

Russell Athletic (Fruit of the Loom, Inc.)

Sainsbury’s – Tu Clothing

Target

Tchibo

Tesco

The North Face (VF Corporation)

The Warehouse

Timberland (VF Corporation)

Tommy Hilfiger (PVH)

Topman (Arcadia)

Topshop (Arcadia)

Uniqlo (Fast Retailing)

United Colours of Benetton (Benetton Group)

Urban Outfitters (URBN)

Van Heusen (PVH)

Vans (VF Corporation)

Warner’s (PVH)

Wrangler (VF Corporation)

Total: 60

Brands who publish raw materials supplier list

Raw material suppliers are those which provide the commodity for the production of clothing e.g. cotton, wool, viscose or polyester.

ASOS

Balenciaga (Kering)

Bottega Veneta (Kering)

C&A

Eileen Fisher

Ermenegildo Zegna

Esprit

Gucci (Kering)

H&M Group

Lululemon

Marks & Spencer

Morrisons (Nutmeg)

Nudie Jeans

Patagonia

SAINT LAURENT (Kering)

Tesco

The North Face (VF Corporation)

Timberland (VF Corporation)

United Colours of Benetton (Benetton Group)

Vans (VF Corporation)

Wrangler (VF Corporation)

Total: 21

Please note: We are not endorsing the brands included in this list; this is not a ‘seal of approval.’ While publishing supplier lists is a necessary step towards greater transparency and improved conditions in fashion supply chains, it does not guarantee ethical business practices. However, we hope you find this list informative and continue to ask brands #whomademyclothes.

This list is not exhaustive and only accurate as of April 2020; if you are aware of other large brands (over £36 million annual turnover) that are publishing their suppliers, please let our Policy and Research team know at transparency@

Fair Trade Fashion From India

Secret Projects is a social enterprise working to ensure that women in India receive a fair wage for their work in the textiles industry. It aims to empower women by providing them with access to the global market for their skills and the products that they make: the final link in the chain they previously lacked.

Secret Projects now works with over 300 makers in six different states in India, making clothing a homeware. The makers are the most integral part of the business, and you are in invited to come and meet some of them:

Meet Lissy, our quality control expert. A former quality controller for Fab India, Lissy works in our Bangalore Production Support Unit checking all our products before distribution to ensure they are of the highest quality. We asked Lissy some questions about her work with Secret Projects…

How did you become a quality checker?

I was working in the garment factory a helper for a year. My supervisor found me diligent and so asked me to take on the role of quality controller. I used to do the measurement and final quality check before products were sent out. This job requires following the entire cycle of the production. But I found the work in the factory very strenuous, and I could not manage it and my family at the same time, as I was never given leave. Then two years ago I came across Secret Projects, and I have been working here ever since.

What do you enjoy most about being part of the Secret Projects team?

I am able to work based on a timetable that is convenient for me. I am not in constant fear that I used to have in my previous jobs, as there is very good support.

What impact has being a quality checker with Secret Projects had on you and your family?

Personally, I am happy to be independent. I am able to manage my children’s school fees with the income. This has meant that I have retained my dignity, as I haven’t had to borrow money. I am no longer stressed, and I feel very happy.

How does it compare to other jobs you have had?

My previous jobs were always based on the management’s needs, whereas this job enables me to negotiate my timetable based on my own schedule.

Deepa is a member of our Bangalore Maker Network.

Deepa, how did you start sewing?

I have always had an interest in sewing, and my husband supported me to become a seamstress. I have been sewing for more than 10 years.

What impact has being a maker had on you and your family?

We were living in a very dilapidated house without much space at home. But through my income, we were able to save up and move into a bigger house that could also accommodate my sewing. This means a lot to me. I feel a sense of gratitude for what I have and am able to do. I hope in the future I can scale up my impact even more.

And what about your wider community?

I live in an urban settlement in Bengaluru. Members of my community often find themselves in distressing situations, and many of them are single mothers. There is a high suicide rate, as they often see no future for themselves. I can proudly say that I have been able to train many of them to sew, and they have found a new lease of life. Initially, when I train them, we support each other in the sewing and share the income. Once they are confident enough, they set up their own sewing unit at home, but it takes a long time to be able to save up to own a sewing machine.

I grew up in a small village. People there are very hard working but don’t have access to many job opportunities. I am keen to take Secret Projects to my village and share the opportunity that I have had with other community members. It would make me really happy to be able to do that.

How does it compare to other jobs you have had?

I used to feel hopeless and un-productive when I was staying at home and only doing household chores and staying at home. Now I feel that my life is so meaningful.

In her own words Nisha is honest, hard working and devoted. Nisha is a 28 year old mother of one. She is also a sewing machine operator at the Echotex manufacturing facility in Dhaka, Bangladesh. 6 months in into her role, the biggest challenge she’s faced is picking up the necessary skills to meet the quality standards required to produce the first NINETY PERCENT collection of premium basics. Every working morning, she says goodbye to her 5 year old son and leaves her home in Shafipur, Gazipur district to catch the rikshaw to Dhaka and make your clothes.

Greatest Achievement:

Being a kind mother to my five year old son is my greatest achievement. It’s hard to find the words to express my love for my boy but I feel heaven’s peace when he runs into my arms for a hug. It makes me so proud to see my tiny boy keep himself neat and tidy and behave well around friends and neighbours.

Work highlight so far:

Completing NINETY PERCENT collection 1 is my greatest career achievement. It was a big challenge for me to make sure the finish was first class. NINETY PERCENT is exclusive product so I had to work hard to assure the quality. I learned a lot making collection 1 and I hope these skills will serve me well in future.

Best memory:

Catching fish as a child. I fished a pond near home in my native village of Bishnupur in the Gaibandha District. The best time to fish was late autumn when the water level was down and it was easier. All the boys and girls fished together then our mothers’ cooked the fresh fish for us.

Favorite place:

Cox’s Bazar – it’s the world’s largest natural sea beach. It’s an amazing feeling by the sea with the breeze and the sand. I’ve never seen any other beaches but I’m sure Cox’s Bazar is the best. Last winter the whole family went there, all the hotels and motels there are world class for all types of foreign and local tourists.

Best life advice?

My parents advised me to always be truthful. I’ve followed this advice at every stage of my life. Wherever I have been or done I have always been truthful. Actually, I think that’s my greatest achievement. It’s advice I passed on to my child – I think that’s why he is so well behaved.

The one thing you can’t live without?

My husband is my life partner – our marriage was arranged by our families. His name is Ashraful Alam and we’ve been living for 10 years. He feels my happiness and pain and tries to help me solve problems. We have a deep understanding of each other – our eyes can read each other’s hearts. My man is wonderful. He always takes care of me and shares what he thinks.

Where do you see yourself in 5 years?

In five years time I wish to be a team-leader. First of all I want to be the best most efficient employee I can – this will see me rise. My supervisor Mr. Azizul’s motivates me and boosts my self confidence. My first day in the job was a mixture of sadness, fear and happiness. I was sad because I thought I would be busy with no more free time to do what I wish. I felt fear because I didn’t know the job or the environment. I felt happy thinking about the money I would earn. Now I wake up in the early morning to complete my family tasks then say bye to my boy and leave for work. When I’m there, I complete my tasks, then return home at 5.30 pm to focus on my family again.

When are you happiest?

I become happiest outside of work when I’m with my family. We spend our time laughing, gossiping and doing lots of things. I love to play chess with my husband and cook – especially mutton curry. Before we go to sleep we always have cup of tea together at the end of the day. Making the tea for everyone is a special moment for me.

C’est en 2012, lors de son premier voyage en Inde que Rhita Benjelloun découvre la lithothérapie: approche holistique de soin, basée sur l’influence subtile, que peuvent apporter les minéraux sur le bien-être de la personne à son contact.

Passionnée de bijoux depuis son plus jeune âge et fascinée par la beauté, l’infini diversité des pierres et leurs pouvoirs énergétiques , elle créera à son retour sa marque rhita créations: des bijoux uniques, réalisés à la main, en argent 925 et sertis de pierres fines venant d’Inde.

Une manière pour elle d’allier la précision que lui impose son métier d’architecte au savoir faire du travail de l’argent de son pays d’origine, le Maroc. Chaque bijoux assemblé est unique et habillé d’une esthétique contemporaine et épurée, où la pierre est travaillée de la manière la plus respectueuse qu’il soit.

Simohammed

Simohammed a 33 ans, et est né à Fès au Maroc.

Chez rhita créations, il s’occupe de l’assemblage à la soudure, du sertissage et polissage. La soudure est ce qu’il préfère: c’est l’étape la plus délicate, car celle-ci doit être parfaite, fine et la plus discrète possible. C’est aussi la phase de la transformation et de la concrétisation du bijoux. Une phase décisive qu’il adore.

Ce qu’il aime le plus dans la vie: Le MAS (équipe de foot de la ville de Fès) et le FC Barcelone 🙂

Quand à moi ce qui me plait dans notre collaboration est d’abord son sourire d’enfant lorsque je lui donne à travailler des pièces compliquées, mais aussi son sérieux et son amour pour le travail bien fait.

Facebook: rhita créations

Instagram: rhita.creations

Fashion Open Studio 2018 – “the only fashion week worth caring about” – expands as a powerful platform for designers and brands to discuss who made your clothes during Fashion Revolution Week. Building on the initiative which started last year, designers from London to LA will be taking part, sharing their processes, ideas and best practice. This is a platform that celebrates transparency in the industry.

The aim of the week-long series of events is to engage the consumer further in the conversation about who makes our clothes – and to involve them in some of the processes along the way.

A diverse range of designers including Stella McCartney, Phoebe English, Christopher Raeburn, Community Clothing, John Alexander Skelton, Roberts|Wood, OneByMe, Katie Jones, Kepler London, Elvis & Kresse x Burberry Foundation, and Vivienne Westwood will each be adding their own voice to a Fashion Open Studio 2018, a week of talks, workshops, picnics and radical quilting.

A highlight of the week will be the Burberry Foundation will be talking about their five-year partnership with Elvis & Kresse to re-engineer waste material through innovative craftsmanship in an open conversation at sustainable luxury visionaries Elvis & Kresse’s Kent HQ.

To kick off Fashion Open Studio 2018, Patrick Grant, founder of Community Clothing and CEO Lucy Clayton will be talking about why – and how – they are trying to revive the British manufacturing and textile industry. Their state of the art Cookson & Clegg factory in Blackburn now has the facility to produce 2,000 garments a month.

They will be joined by fellow industry veteran (ex Topshop, Asos and Finery London) Caren Downie, who recently launched her own Made in Britain glasses brand ByOcular. The opening event is supported by CELC – Master Of Linen, who will launch the I Love Linen campaign collaboration with Chelsea College.

MEET AND MAKE

Fashion Open Studio is a rare chance to meet and make with some of London’s most exciting young designers and their teams including Kepler London who will be opening up their Ridley Road studio to talk about how thy work and show some of their innovative knit pieces in production.

The designer cooperative Congregation who will be hosting a 3-day workshop to engage the public and create new work. They will be creating new pieces from the previously discarded. The pieces will be passed from designer to designer, each adding their own thoughts and expertise along the way and allowing them to develop into an unpredictable outcome.

All are finding new ways of producing their collections so they can take greater environmental and social responsibility for their fabric choices, supply chains and production processes.

Fashion Open Studio is a great way to learn new skills from some of the industry’s most exciting talent. There will be a rare opportunity to join Phoebe English at her Deptford Creek studio in her Quilting From Waste workshop, using her waste fabric from the past year. She is looking forward to having time to join the stitching, to discuss waste, recycling, and how to combat mass consumption. The activist artist and poet Wilson Oryema will be on hand to read from his recently published book, Wait.

The acclaimed accessories designer Michelle Lowe-Holder will be hosting a ribbon reclaim jewellery making workshop.

And to end the week, one of the most innovative design duos, OneByMe will be hosting the launch of their ONELAB, a social enterprise which will encourage people to create their own garments like the OneByMe One Piece T-shirt. HOW WILL YOU MAKEIT will be an opportunity to try our hand at making your own piece of ONEBYME. This radical new brand is finding a new way of making fashion based around circularity. Any waste fabric is fed to their wormery. Cocktails using herbs grown from the resulting compost will be served.

In partnership with Sarabande: The Lee Alexander McQueen Foundation, there will be two talks. Fashion Open Studio curator Tamsin Blanchard will be discussing the merits of slow fashion with Sarabande designers John Alexander Skelton and Roberts|Wood.

DISRUPTING THE RETAIL INDUSTRY

Fashion Open Studio is excited to announce a partnership with the social online clothing marketplace Depop, to promote the Nothing New open studio event, focusing on why vintage classics are all you need. 40 % of 18-24 year-olds bought second hand clothing last year. Second hand clothing sites like Depop and The RealREal are changing the retail landscape, giving clothes a longer life and slowing the sale of new clothes. The Depop event at Protein Studios will be a chance to meet some of Depop’s own community of sellers and will feature an exhibition of iconic items and their story throughout the years. There will also be a workshop by the extraordinary footwear artist Helen Kirkum.

Remade Reduced Recycled is the Christopher Raeburn mantra. For Fashion Open Studio, Raeburn will be hosting Raeburn Repairs, an open day of free repairs. Guests will be welcome to bring along their favourite items that are in need of a little TLC to be repaired and remade as good as new (if not better). “In a world of overconsumption and fast fashion, one of the most radical thing we can do as consumers is to keep our clothes in use for as long as possible,” says Raeburn. We couldn’t agree more.

DO SOMETHING

Fashion Open Studio is a global event and will include workshops, talks and studio tours around the world. Highlights include:

Melbourne, A.BCH will be sharing the transparency story behind their basics brand, with Cutpiece, a series of up-cycling workshops. Participants are invited into the studio to make a new item from old clothing, off-cuts or salvaged materials. Participants will be able to choose their own adventure and skill level by choosing one of three workshops to be held throughout Fashion Revolution Week.

And in Shanghai, LVMH-shortlisted designer Xu Zhi will be opening up his Chinese studio with a rare opportunity to see some of his production techniques and craft.

In Buenos Aires, Manto Abrigos will be hosting daily events at their showroom to talk about the stories behind their brand, the sociology of fashion, and the close connections with the artisans who make the clothes.

In Jakarta, Manual Jakarta presents Fashion Revolution Open Studio: Wilsen Willim, supported by British Council Indonesia and also Fashion Revolution Indonesia.

In New York and LA, Stella McCartney is celebrating her recent partnership with the consignment website The RealReal with in store events designed to inspire customers to care for, repair and prolong the life of their clothes so that they can have a second life as part of a circular economy.

Check out Fashion Revolution Open Studio events page for details of an event near you.

‘We want to celebrate the invisible process behind designers finished collections, the intimacy of a studio, the reality of the team, and see the people that make out clothes’ Orsola de Castro

‘This year’s Fashion Open Studio is such an exciting mix of creativity and new ideas. It is all about collaboration and making a different kind of fashion community. Open Studios is an opportunity to shine a light on a group of emerging designers – and some established trailblazers – who are finding alternative ways of producing fashion that is mindful of the makers, the planet, and its resources. They all work in very different ways and are at different stages in their journey but are united in their mission to make fashion better.’ Tamsin Blanchard, curator, Fashion Open Studio

Fashion Revolution Week, April 23-29 is a global campaign sparking a wider public conversation about the impacts of our clothes on the people who make them.

Fashion Revolution Week is here again and its mission remains unchanged: to campaign in a positive way for greater transparency in fashion supply chains. For a brand to be able (and willing) to publish details of its supply chains means that they are far more likely to be working ethically: safe, clean and fair. And knowing the true provenance of your purchases empowers you, the consumer, to make fully informed buying choices.

We’re not only willing and able to tell you about where and who our baskets come from – you can’t usually stop us shouting about the weavers and their incredible craft! We visit as many cooperatives as we can throughout the year and we’re in daily communications with most cooperative chairladies during the dry seasons when the weaving steps up a gear. It’s vitally important for us to build relationships and empathy with the people behind our baskets; to hear their stories and to see how they live. We hope that you enjoy hearing their stories, too.

Spoiled for choice as we were for whom to feature in this blog post for Fashion Revolution Week (so many interesting and inspiring people to talk about), we have decided to tell you a little more about a weaver named Ntomulan Lesania, who makes some of our Nomadic Beaded Baskets from her home in rural Ngurunit, Northern Kenya.

Back in March 2017, Camilla headed out to meet the Ngurunit Weavers Group. These weavers are semi-nomadic pastoralists (herding camels, cattle, sheep and goats) known collectively as Ariaal: they don’t belong fully to either the Samburu or the Rendille tribes – Ariaal is a mixture of the two. The Ariaal people are known for their peaceful ways and their openness to compromise, merging characteristics from both traditions – in house building, in bead making and in handicrafts – and speaking the two tribal languages interchangeably.

Ntomulan Lesania is a single mother: widowed, with six children aged between 3 and 18. She was her late husband’s second wife, and she had three children before marrying him – and then went on to have three more children with him. Here are some excerpts from Camilla’s interview with her:

The multi-coloured layers of beaded collars, headdresses and earrings worn by the Samburu women denote not only marital status but also other clues as to a woman’s rank within the tribe. Beads, buttons and sequins in different colours can signify anything from her husband’s wealth to how many sons she has birthed.

Where did you grow up and did you go to school?

I grew up in Ngurunit. I didn’t go to school. Instead, I looked after the animals in my family: goats and camels.

Do your children go to school?

Four of my six children go to school. Two boys, and two girls. The youngest two look after the family animals. I have to pay for them to attend school. Primary school is free, but secondary school is fee-paying.

Not all the children here go to school. Children who are especially good at looking after the animals will usually stay home, whilst their siblings might attend school. Sisters from the same families will sometimes be dressed differently: those who were educated will often wear more Western clothes, whilst their siblings who did not attend school wear traditional Samburu beads.

How do you make the money to pay for schooling?

I make money through basket weaving, and selling livestock, and goat and camel milk. We receive camels when we get married and we invest in livestock when we save enough money. The current drought means that livestock are dying, however. There is more drought in the area than ever before. If there are one or two failed rains, this is considered a drought, and life becomes hard for people and their businesses. Since 2006 there have been no consecutive years without drought. Recovery from a drought can take up to a year.

Life has changed considerably for Ariaal women in recent years. In this rural region of Kenya where milk is precious currency, women are now allowed to own milk-producing camels as well as milk itself. When Camilla visited in March 2017 the drought was very bad and governmental parties were slaughtering cattle to be eaten by their owners, then paying the owners for the value of that animal. This is a scheme called Food Relief, and serves the dual purposes of putting the animals to good use so that they do not starve, and feeding the people without seeing them out of pocket.

How long have you been weaving for and how did you learn?

I saw my older sister weaving, and learnt the art from her. She was only just married at that time, so still a teenager.

How does the income from the weaving help support your family?

The income from weaving helps me to buy food, pay school fees, and pay for school transport.

What makes you happy?

When my kids are around me, and we have no problems. When I am able to feed them all, and when they are happy.

What do you feel would help women to overcome the barriers they face in the working world?

More basket orders. Money helps to solve problems here. We need to earn a living.

Do you feel successful being part of a growing weaving cooperative?

Yes. We are all proud! This group is important to me: it gives me support. I am a single mother, and I get help from my friends. If I have an order to deliver, for example, my friends will help me with the children.

Ntomulan’s woven baskets – the Pambo Palm collection – were traditionally created by the Rendille people as vessels for collecting camels’ milk.

Fashion Revolution Week falls on the anniversary of the Rana Plaza factory collapse, which killed 1138 people and injured many more, on 24th April 2013. During this week, brands and producers are encouraged to respond with the hashtag #imadeyour… (insert product) and to demonstrate transparency in their supply chain.

Marcelo Ballesteros, age 50, has worked with animaná for two years now as the link between the company and the local artisans who live in more remote regions of the area. A retired marine, Marcelo now lives in the city of Salta, Argentina and was referred to animaná by a friend of the brand’s founder, Adriana Marina. Since he used to work with his father on pottery and crafted mats on handlooms as a child, he has prior knowledge of handicrafts. When Adriana asked if he would like to act as the connection between animaná and the artisans, Marcelo accepted the offer as an amazing chance to explore and meet new people.

“A day of work for me is never the same as the other.”

Generally, Marcelo’s day begins by preparing the vehicle, writing the waybill and noting the artisans he needs to visit. Sometimes, he explains, you can find them easily and sometimes not. If they are far off in the country feeding the llamas or sheep, it can take up 3 or 4 hours to walk from their houses. At times, Marcelo will sleep in the places he visits if the travel time makes it too difficult to get in and out in one day. Each exertive working day, however, is finished with a big smile because of the adventure lived.

Due to the diversity of locations and unstructured nature of the meetings, it is impossible to stipulate how long each visit will take. Marcelo describes these trips as traveling into the past where there are no mobile phones or televisions — just nature. Kids are the same color as their surroundings and always playing with their herds of llamas or sheep.

“You can feel the flowing streams. The sky is blue, and there is such a cleanness that you forget where you come from. You take some time and think that you are in an amazing place with amazing people, and that is when you realize that the way the village, that is so far from common luxuries, is able to give their touch to the world, is through their crafts.”

Marcelo’s work contributes to the people of the Andes by creating community links and building personal relationships. At times the artisans will travel to Salta and visit Marcelo at his home. He is always ready to assist them and makes sure they are aware of just how much their hard work is valued. What he enjoys most about this bond is being able to talk with the artisans and hear about their lives in the mountains. As he puts it, it creates a link of friendship that goes beyond the commercial.

His hope for the future is that travel routes can be open every month of the year because now, in the rainy seasons, it is impossible to access the remote areas. He also dreams of easier transport for the artisans into the city, as it is only possible now with a pickup truck and at an expensive cost. Still, Marcelo and animaná work tirelessly to bridge the distance between commerce and the local artisans, and through their dedication they are able to foster relationships that extend beyond business.

“Never stop dreaming.” -Marcelo Ballesteros

Their story began with a splendid white dress shirt made by a smiling tailor in an alley of HoChiMinh City, Vietnam. Beyond the singular experience of wearing bespoke garment for the first time, it is the direct purchase from its maker that was the trigger. “Each of us now wants products that answer one’s individual needs”, says Bernard, “I hate shopping malls and I love buying unique items. I am fascinated by nice objects and the stories behind them. That’s how the idea to create an ecommerce marketplace for custom made clothes and accessories handmade in South East Asia came out.”

For the Belgo-French duo, Bernard Seys and LouAdrien Fabre., connecting consumers directly with makers creates better outcomes for everyone. As the sole vendors on efaisto.com, makers are in full control of their pricing. They receive up to 85% of what the customer pays, net of all fees.

https://www.youtube.com/watch?v=edHJvRvx71o&feature=youtu.be

As each item is made on demand, the makers do not have large production batches, minimum order quantities nor canevas to follow. By essence, each bespoke product has to be cut, sewn, dyed, engraved, polished or coated individually by human hands. Which results in a drastic reduction of waste or unsold products and an increased average lifetime of the product.

The buyers have the opportunity to get tailored clothes and custommade accessories at a fair prices, and know who made them.

La semana pasada en Copenhagen Fashion Summit, Juan Orlando Hernández, Presidente de Honduras hizo la siguiente invitación: “Si quisieran ir a Honduras a conocer por ustedes mismos, yo los recibiré personalmente en el aeropuerto”.

Ignorando las molestias en la parte posterior del auditorio que llamaron “Señor Presidente, detenga a los militares de asesinar a activistas” el Presidente de Honduras lanzó para promocionar el país como líder de exportación de prendas a Estados Unidos de América y tiene el objetivo de exportar más al mercado Europeo. La industria del vestir y textil es parte del nuevo plan Honduras 2020, un proyecto de $3.4 miles de millones, que tiene como meta hacer que Honduras sea la elección de muchas marcas para proveer de forma sustentable. “Haremos esto mediante un verdadero modelo sustentable, enfocándonos en factores clave como condiciones laborales sustentables, protección del medio ambiente, utilizando la última tecnología para reducir el consumo de los recursos, cambiando los combustibles a energías renovables” mencionó Juan Orlando Hernández, quien continuaba enfatizando el objetivo de su país por tener el 80% de sus energías de origen renovable para el 2020.

El compromiso por reducir los combustibles no renovables claramente no exenta al mismo Presidente, quien rentó un jet de lujo para ir a la conferencia de Vista Jet, entre sus clientes tienen a celebridades como Beyonce y los Beckham. La presentación del Presidente le costaría $360,000 viajando solo, de acuerdo con la información del sitio, dando esto decenas de críticas en la página de Facebook de Copenhagen Fashion Summit.

El Presidente seguía mencionando a las 1200 personas del público haciendo hincapié en cómo su país toma muy en serio el lado social de la sustentabilidad. “Gozamos de un excelente y seguro ambiente de trabajo y cuidar a nuestra gente es nuestra principal atención y responsabilidad”.

El Presidente llegó a decir que Honduras era “el segundo lugar más justo para la producción de prendas de vestir”. Después de un correo electrónico al Americas Apparel Producers’ Network, he recibido una respuesta del Director General Mike Todaro quien aclaró que el Presidente se refería al AAPN Asia/Americas Report Card. Honduras llegó al 2º lugar en el informe. Sin embargo, por lo que yo puedo ver a partir de la información en línea, sólo uno de los 8 criterios se refiere a cumplimiento social y sostenibilidad y los otros 7 incluyen elementos como el coste, la velocidad y el desarrollo de productos.

De acuerdo con War on Want, 53% de los trabajadores en maquilas o fábricas de ropa, en Honduras son mujeres jóvenes de comunidades desfavorecidas que tienen poca educación. La mayoría no son conscientes de sus derechos, la explotación es frecuente y los trabajadores están desmotivados a formar sindicatos. Solidarity Center dice que los sindicalistas son constantemente amenazados, intimidados, extorsionados e inclusive asesinados, y los criminales rara vez puestos a disposición judicial.

31 sindicalistas han sido asesinados y 200 heridos en ataques desde el 2009, de acuerdo con la federación de sindicatos AFL-CIO. De hecho en Marzo del año pasado en Departamento Americano del Empleo publicó un informe documentando abusos a los derechos de los trabajadores en Honduras. El informe detalla muchos casos donde los empleados hondureños relacionados en actos de discriminación anti-sindicalistas, imponiendo pactos anti-sindicalistas para frustrar negociaciones colectivas, así como casos donde no se pagan los salarios, exigir horas extras y numerosos abusos en cuanto a salud y seguridad laboral.

En promedio los salarios de las maquilas son equivalentes al 37% del costo de la canasta básica de Honduras. Además la diferencia entre los salarios de los trabajadores de maquilas y los de las otras industrias está en crecimiento. La competencia a la base continuará a menos que tomemos un acercamiento para tener un salario para vivir, trabajando con los gobiernos y sindicatos para ajustarlo de manera legal, imponiendo un salario mínimo en su país que asegure que los empleados puedan cubrir sus necesidades básicas.

Sin transparencia en la cadena de suministro y sin compromiso de los dueños de las marcas de moda y las fábricas de invertir en mejores condiciones laborales, los salarios y derechos de los trabajadores se mantendrán desempoderados y no podrán negociar de manera independiente sus condiciones laborales.

La industria textil y de la moda sin duda a traído trabajos al país, pero no son buenos empleos. Frecuentemente se discute si cualquier trabajo es mejor que no tener trabajo, pero no hay motivo por el cual no crear buenos empleos, trabajos con dignidad, sin tener un impacto en el precio de venta. El hecho de que la gente está en una situación difícil no es motivo para explotarla. Una Fashion Revolution es necesaria dado que las marcas, incluso las mejores marcas quienes están trabajando de manera proactiva hacia un salario para poder vivir, nunca cambiarán el sistema.

Deberían venir a ver si estos empleos realmente ayudan a las personas a salir de la pobreza, con los salarios que reciben, sin derechos laborales. ¡No tienen un lugar para sentarse a comer, tienen que comen en las calles y regresar al trabajo! ¡En verdad se creyeron lo que este hombre fue a decir a su evento! Comentó RS Briose en la página de Facebook de Copenhagen Fashion Summit.

En respuesta a RS Bruise y otros ciudadanos Hondureños quienes comentaron sobre la visita de Juan Orlando Hernández a Copenhagen Fashion Summit: Sí, visitaremos y veremos con nuestros propios ojos #whomademyclothes #quienhizomiropa. Iremos a ver si Honduras es realmente uno de los lugares con las mejores condiciones sociales en el hemisferio oeste para la producción de ropa y textiles, tal y como se indica en la presentación del Presidente.

Estoy lista para aceptar el ofrecimiento del Presidente de Honduras para visitar las fábricas de su país y confío en que mantendrá su palabra. Presidente, nos vemos en el aeropuerto.

At the Copenhagen Fashion Summit last week, Juan Orlando Hernández, President of Honduras, issued the following invitation: ‘If you would like to go to Honduras to look around for yourselves, I will be personally at the airport waiting for you’.

Ignoring the heckler at the back of the room who called out ‘Mr President, stop the military from murdering community activists’ the President of Honduras launched into a promotion for his country as a leading garment exporter to the US and his ambitions for a larger European market share. The garment and textile industry is part of the newly launched Honduras 2020, a $3.4 billion project which aims to make Honduras into the country of choice for brands and retailers wishing to source sustainably. ‘We will do this through a real sustainable model focussing on key topics such as sustainable working conditions, protecting the environment, using the latest technology to reduce consumption of resources, moving from fossil fuel to renewable energy sources’ stated Juan Orlando Hernández, who continued by highlighting his country’s ambition to source 80% of its energy from renewable sources by 2020.

The commitment to reduce fossil fuels clearly doesn’t extend to the President himself, who rented a luxury jet to fly to the conference from Vista Jet, whose clients include celebrities such as Beyonce and the Beckhams. The President’s short presentation would have cost $360,000 in travel alone, according to one source, prompting dozens of critical comments on the Copenhagen Fashion Summit Facebook page.

The President continued to address the 1200-strong audience by underlining how seriously his country takes the social side of sustainability. ‘We enjoy an excellent and safe work environment and taking care of our people is our main focus and our responsibility’.

The President went on to say that Honduras was ‘the second most fair location for garment production’. After an investigatory email to the Americas Apparel Producers’ Network, I received a response from Managing Director Mike Todaro who clarified that the President was referring to the The AAPN Asia/Americas Report Card. Honduras came 2nd overall in the AAPN Report Card which is completed by sourcing executives. However, as far as I can see from online information about the Report Card, only one out of the 8 criteria relates to social compliance/sustainability and the other 7 include elements like cost, speed and product development.

According to War on Want 53% of garment workers in maquilas, or garment factories, in Honduras are young women from deprived backgrounds who have little education. Most are unaware of their rights, exploitation is widespread and workers are actively discouraged from joining unions. The Solidarity Center says trade unionists are routinely threatened, intimidated, harassed and even murdered, with the criminals rarely brought to justice.

31 trade unionists have been assassinated and 200 injured in attacks since 2009, according to the umbrella federation for US unions AFL-CIO. In fact, in March last year the US Department of Labour issued a damning 143 page report documenting widespread and serious violations of labour rights in Honduras. The report detailed numerous cases where Honduran employers engaged in acts of anti-union discrimination, imposing non-union pacts to frustrate collective bargaining, as well as cases of non-payment of wages, forced overtime and numerous occupational health and safety violations.

On average, the wages earned in maquilas are equivalent to only 37% of the cost of the basic basket of consumer goods in Honduras. Moreover, the gap between wages for workers in maquilas and those in other industries is widening. The race to the bottom will continue unless we take a systemic approach to the issue of a living wage by working with governments and unions to set a legal, enforceable minimum wage in their country which ensures workers can meet their basic needs.

Without supply chain transparency and a commitment from fashion brand owners and factories to invest in better working conditions, living wages and workers’ rights, garment workers will remain disempowered and unable to independently negotiate labour conditions.

The garment and textile industry has undoubtedly brought jobs to the country, but not necessarily good jobs. It is often argued that any job is better than no job, but there is no reason why we can’t be creating decent jobs, jobs with dignity, without any significant impact on the retail price. The fact that people are desperate isn’t an excuse to exploit them. A Fashion Revolution is needed because brands, even the best of the brands who are working most proactively towards a living wage, will never change the system.

‘You should come see if this jobs really help people get out of poverty, with the kind of wages they make, with no labor rights. They are not even given a place to have their meals, they have to take lunch in the street and then come in back to work! Did you really believe what this man went to say to your event!’ commented RS Bruise on the Copenhagen Fashion Summit Facebook page.

So, in response to RS Bruise and all the other Honduran citizens whose commented on the visit of Juan Orlando Hernández to the Copenhagen Fashion Summit: Yes, we will come and see for ourselves #whomademyclothes. We will come and see whether Honduras really is one of ‘most fair social locations in the Western hemisphere for garment production’, as claimed in the President’s presentation.

I am ready to take the President of Honduras up on his offer to visit garment factories in his country and trust that he will keep his word. Meet me at the airport, Mr President.

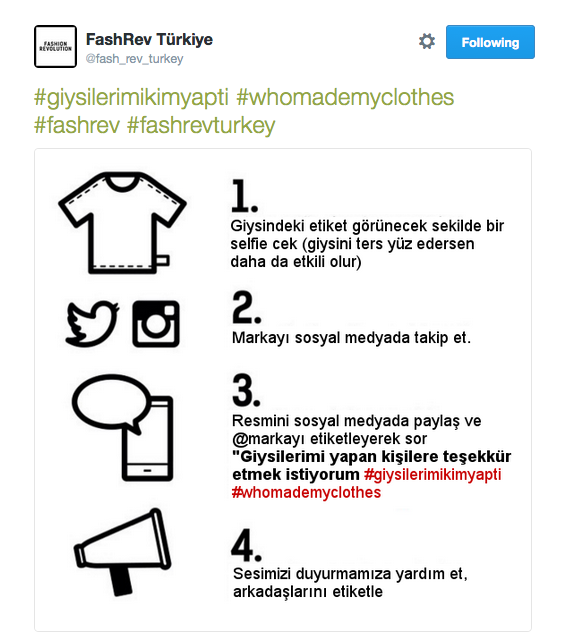

This year, Fashion Revolution Week took place in 89 countries around the world. One of these countries was Turkey.

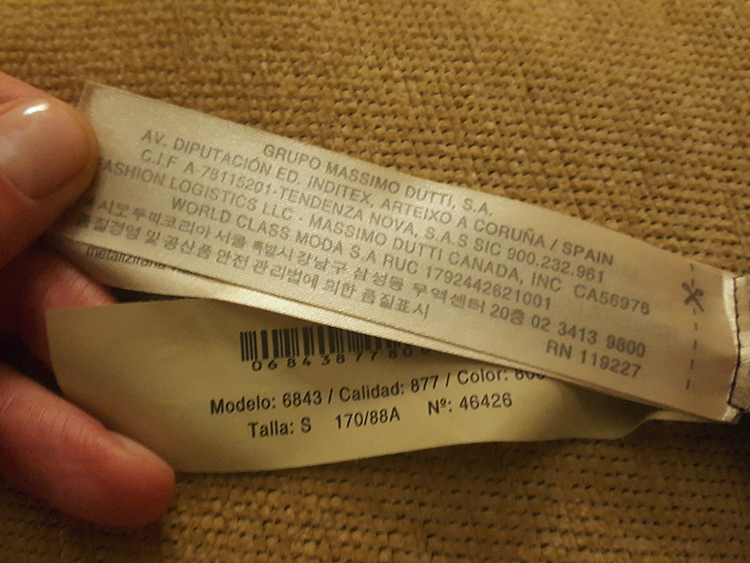

Deniz Ucok saw this post and decided to ask Massimo Dutti who made her T-Shirt #whomademyclothes?

Massimo Dutti is a Spanish clothes manufacturing company, founded in 1985, which is part of the Inditex group. Massimo Dutti is not a real person, but a trademark. Despite the Italian name, it is a Spanish company employing over 4000 people worldwide.

Massimo Dutti responded by asking Deniz to send them a photograph of the labels in her T-Shirt.

And Massimo Dutti certainly can answer the question #whomademyclothes, as shown by their comprehensive answer below.

Dear customer,

The item you requested information about was purchased from a Portuguese Company for the Summer collection 2016. The name of our supplier is Vieira & Marques, Lda. and their facilities are located at San Martinho Campo. It has 180 employees and it received the highest score during our latest social audit which will be revised again throughout this year (2016.)

During the manufacturing process other Portuguese companies have intervened:

For fabric manufacturing: Vilartex Emp de Malahas V Lda based in Guimaraes and with 106 employees.

For tinting processes: Carvitin Tintura e Acabamentos Lda, based in Coimbra with 56 employees.

For confection: M Look Confeccoes based in Fomelos with 40 employees.

For ironing: Jose Amorim Mota Unipessoal Lda, based in Guimaraes with 67 employees.

All these factories have been examined by our social audits as well as production audits that assure the clothing traceability.

We hope you find this information useful.

Kind regards,

Massimo Dutti

Deniz replied to Massimo Dutti on Twitter.

Inditex scored 76% overall in Fashion Revolution’s Fashion Transparency Index, published on 18 April, just one percentage point behind the leader, Levi Strauss & Co. To find out more about the scoring and methodology of the index, please read our Top 10 FAQs